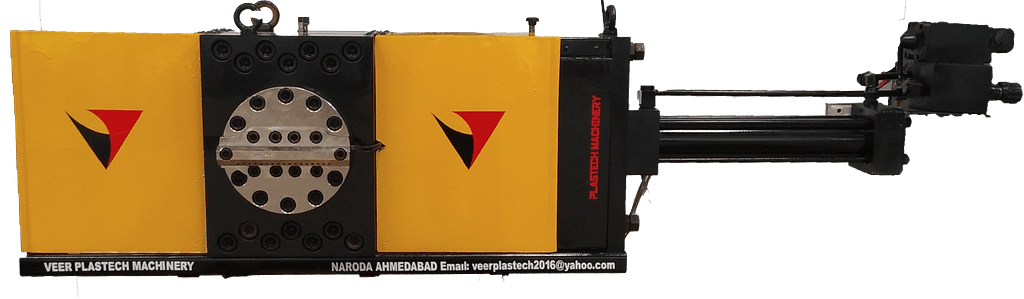

A Plunger Type Hydraulic Screen Changer Machine is a specialized equipment used in plastic extrusion processes to filter contaminants from molten plastic materials. Here’s a detailed explanation of its components, functionality, and applications:

TECHNICAL SPECIFICATIONS:

| Usage/Application | Industrial |

| Frequency Hz | 50Hz |

| Voltage V | 220 V |

Application

- Packaging Industry:

- Used in the production of plastic films and sheets for packaging applications, ensuring high-quality output free from contaminants.

- Construction:

- Produces pipes, profiles, and other construction materials with consistent quality and purity.

- Automotive:

- Manufactures plastic components used in automotive applications, where cleanliness and quality are critical.

- Recycling:

- Facilitates the recycling of plastic materials by filtering out contaminants, contributing to sustainable production practices.

- Consumer Goods:

- Used in the manufacturing of various consumer goods where precise control over material purity and quality is essential.

Key Features:

- Continuous Operation:

- Enables uninterrupted production by allowing screen changes without stopping the extrusion process.

- Reduces downtime and increases overall efficiency of the production line.

- Hydraulic System:

- Utilizes hydraulic pressure to actuate the plunger, facilitating smooth and controlled screen changes.

- Provides sufficient force to push out used screen packs efficiently.

- Screen Packs:

- Consist of multiple layers of screens with different mesh sizes tailored to specific filtration needs.

- Screens can be easily replaced or cleaned, maintaining optimal filtration performance.

- Heating Elements:

- Ensures consistent temperature of the molten polymer as it passes through the screen pack, preventing premature solidification or degradation.

- Pressure and Temperature Control:

- Incorporated sensors and controls monitor and maintain ideal processing conditions.

- Helps in preventing equipment damage and ensuring product quality.

- Versatility:

- Suitable for a wide range of plastic materials and extrusion processes, including but not limited to:

- Blown film extrusion

- Sheet extrusion

- Pipe and profile extrusion

- Compounding and recycling processes

- Suitable for a wide range of plastic materials and extrusion processes, including but not limited to:

- Quality Assurance:

- Filters out contaminants such as gels, paper, metal particles, and other impurities from the molten polymer.

- Enhances the quality and purity of the final extruded product.

- Ease of Maintenance:

- Designed for easy access to the screen packs and hydraulic components for routine maintenance and cleaning.

- Minimizes downtime associated with maintenance activities.

- Safety Features:

- Incorporates safety mechanisms to prevent accidents during operation, such as interlocks and emergency stop buttons.