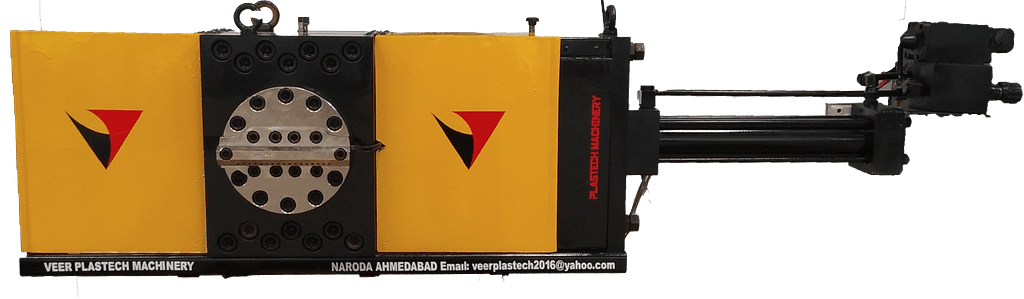

Our Hydraulics Side Plate Type Screen Changer Machine is designed for efficient and uninterrupted filtration in extrusion processes. This state-of-the-art equipment ensures minimal downtime and maximum productivity by facilitating continuous screen changes without stopping the production line.

TECHNICAL SPECIFICATIONS:

| Usage/Application | Screen Changer |

| Working Pressure | 10000 PSI |

| Material | Mild Steel |

| Color | Yellow |

| Frequency Hz | 60 Hz |

| Voltage V | 220 V |

| Automatic Grade | Semi-Automatic |

Applications:

- Plastic extrusion

- Polymer processing

- Rubber and elastomer extrusion

- Compounding and masterbatch production

Features

- Hydraulic Operation:

- Utilizes advanced hydraulic systems for quick and seamless screen changes.

- Reduces manual intervention, increasing operational efficiency and safety.

- Side Plate Design:

- Innovative side plate mechanism allows for easy access and maintenance.

- Compact design saves space while ensuring robust performance.

- Continuous Operation:

- Enables continuous production with no need to halt for screen replacement.

- Ideal for high-volume extrusion processes requiring uninterrupted workflow.

- High-Quality Filtration:

- Ensures superior filtration of contaminants, enhancing product quality.

- Suitable for processing various materials, including plastics and polymers.

- Durable Construction:

- Built with high-grade materials to withstand demanding industrial environments.

- Ensures long-term reliability and durability, reducing maintenance costs.

- Easy Integration:

- Compatible with a wide range of extrusion lines.

- Simple installation process, allowing for quick setup and integration into existing systems.