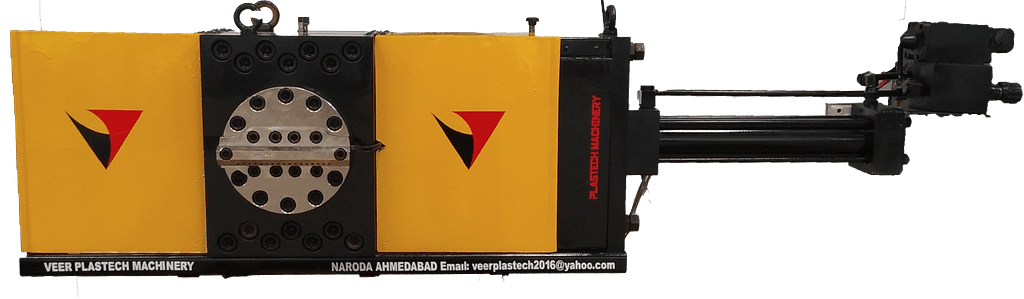

Our Dana Machine Screen Changer is designed to enhance the efficiency and quality of plastic reprocessing and extrusion operations. This state-of-the-art machine allows for continuous screen changes without halting production, ensuring a seamless and productive workflow.

TECHNICAL SPECIFICATIONS:

| Machine Type | Automatic |

| Power Consumption | 20 Watt |

| Material | Mild Steel |

| Mounting | Floor Mounting |

| Pressure | 1000 PSI |

| Usage/Application | Plastic Industry |

| Country of Origin | Made in India |

| Voltage | 220 V |

| Frequency | 50Hz |

Application

- Plastic reprocessing

- Extrusion processes involving Dana machines

- Production of plastic pellets and granules

Benefits:

- Increases productivity with continuous operation.

- Ensures high-quality output through effective filtration.

- Reduces downtime and maintenance costs.

- Enhances operational safety and efficiency.

Key Features

- Hydraulic Operation:

- Equipped with a high-performance hydraulic system for fast and efficient screen changes.

- Reduces manual labor, improving operational safety and efficiency.

- Durable Construction:

- Built with high-quality materials to withstand demanding industrial environments.

- Ensures long-term reliability and minimal maintenance requirements.

- Continuous Production:

- Enables uninterrupted production by allowing screen changes without stopping the process.

- Ideal for high-volume operations, ensuring consistent and efficient output.

- Superior Filtration:

- Effectively removes contaminants to ensure the high quality of processed materials.

- Suitable for a wide range of plastic materials used in Dana machines.

- Easy Integration:

- Designed to integrate seamlessly with existing Dana machines and extrusion lines.

- Quick and straightforward installation process for minimal downtime.

- User-Friendly Operation:

- Features intuitive controls for easy operation and maintenance.

- Enhances productivity by simplifying screen changes and reducing downtime.