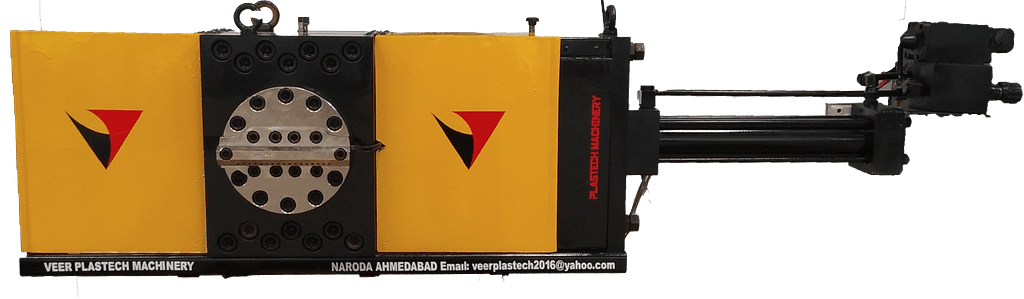

Our Dana Machine Extruder Screen Changer Machine is designed to enhance the efficiency and quality of plastic extrusion processes. This advanced machine allows for continuous production by facilitating seamless screen changes, ensuring a smooth and uninterrupted workflow.

TECHNICAL SPECIFICATIONS:

| Power Consumption | 20 Watt |

| Material | Mild Steel |

| Mounting | Floor Mounting |

| Usage/Application | Plastic Industry |

| Country of Origin | Made in India |

| Frequency | 50Hz |

| Voltage | 240V |

Application

- Plastic extrusion processes

- Production of plastic pellets and granules

- Polymer and rubber extrusion

- Film and sheet extrusion

Benefits:

- Increases productivity with continuous operation.

- Ensures high-quality output through effective filtration.

- Reduces downtime and maintenance costs.

- Enhances operational safety and efficiency.

Key Features

- Hydraulic Operation:

- Equipped with a high-performance hydraulic system for fast and efficient screen changes.

- Minimizes manual labor, improving operational safety and efficiency.

- Robust Design:

- Constructed with durable materials to withstand the rigorous demands of extrusion processes.

- Ensures long-term reliability and minimal maintenance requirements.

- Continuous Production:

- Enables uninterrupted production by allowing screen changes without stopping the process.

- Ideal for high-volume operations, ensuring consistent and efficient output.

- Superior Filtration:

- Effectively removes contaminants to ensure the high quality of extruded materials.

- Suitable for a wide range of plastic materials used in Dana machines.

- Easy Integration:

- Designed to seamlessly integrate with existing Dana machine extruders and extrusion lines.

- Quick and straightforward installation process for minimal downtime.

- User-Friendly Operation:

- Features intuitive controls for easy operation and maintenance.

- Enhances productivity by simplifying screen changes and reducing downtime